About Jam Silica Processing Products

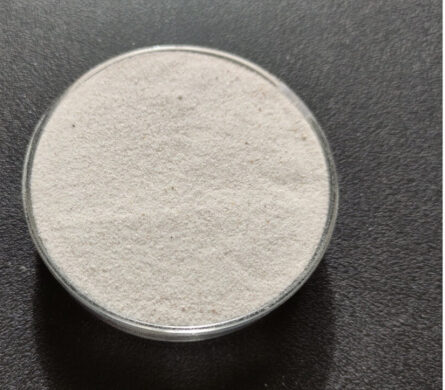

Among all minerals, quartz is an almost pure chemical compound with stable physical properties abundant in nature. This mineral has a hardness of 7 on Mohs scale and its density is 2.65 grams per cubic centimeter.

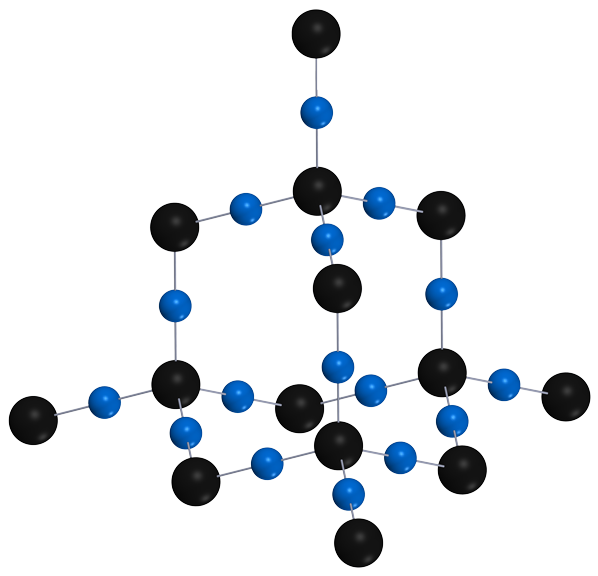

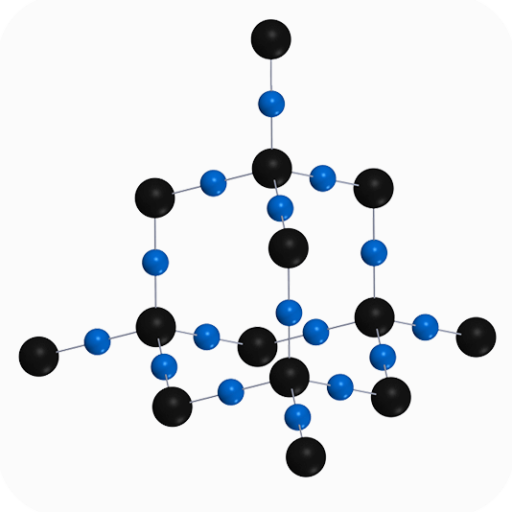

Quartz stone is a SiO4 compound in which each silicon is attached to 4 oxygen and has a rhombic structure. The main mineral is silicon quartz crystallized and reveals all its physical and chemical properties in this condition. Quartz is not sensitive to most acids and bases except fluorhydric acid.

Jam Silica Processing Products

Registration Orders

In this section you can request your order so that our company can contact you as soon as possible and answer any possible questions you might have and complete your order registration process.

Jam Silica Processing Address

factory

kohrasanRazavi, Torbat Jam

Industrial Park, Farhang Street

(051)-52548004

Mashhad Sales Office

Rahnemayi Street, 8Th rahnemayie

Momtaz Building, 3rd Floor

(051)-38477960-61

Torbat Jam Sales Office

jami Street

Number 73

(051)-52523052